The Industrial Engineering Department is equipped with a comprehensive array of specialized laboratories that provide students with hands-on experience and practical knowledge in various aspects of industrial engineering. These labs are integral to bridging the gap between theoretical concepts and real-world applications, ensuring that students are well-prepared for successful careers in engineering and technology. The department's laboratories include the follwings.

WORK STUDY LABORATORY

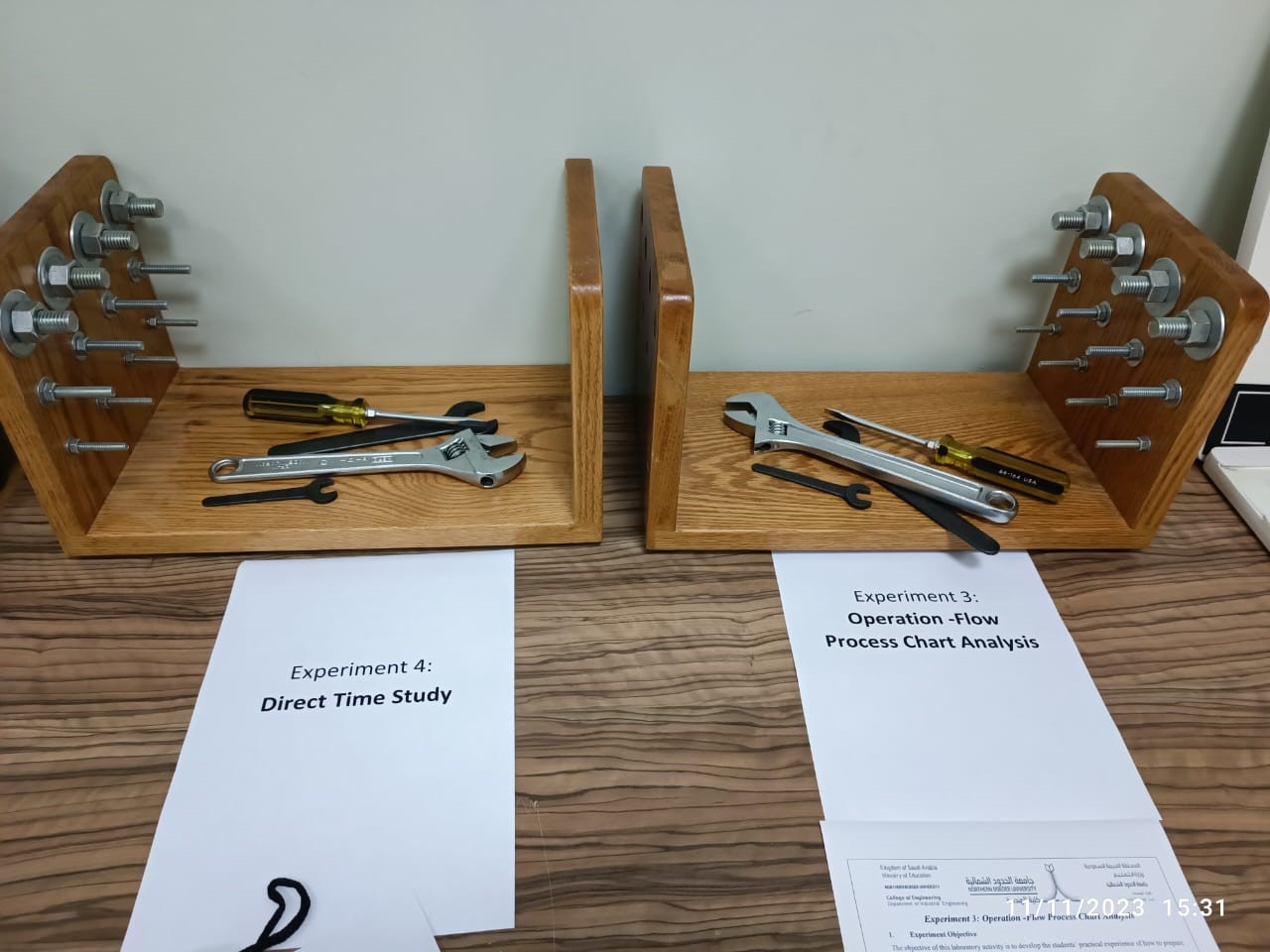

Assembly Task Workstation for Time and Motion Study

Overview

The Work Study Laboratory is dedicated to the systematic analysis and optimization of work processes. It plays a crucial role in teaching students the principles of time and motion studies, which are essential for enhancing productivity and efficiency in industrial operations. Through hands-on experiments, students learn how to identify inefficiencies, streamline workflows, and eliminate waste in diverse industrial settings.

Key Features

Assembly Task Workstation: This workstation is designed to simulate real-world assembly processes using tools such as wooden boards with bolts and nuts. Students conduct experiments to identify inefficiencies, develop process enhancements, and apply theoretical concepts to practical tasks.

Time and Motion Studies: Students utilize tools like stopwatches and experiment sheets to perform detailed analyses of task sequences, identifying bottlenecks and optimizing workflows. They learn to document processes and measure time taken for different methods or conditions, which is critical for improving efficiency.

Predetermined Motion Time System (PMTS): This setup employs tools like cylinders and disks to measure task durations, helping students establish standard times and streamline operations. The PMTS provides a foundation for evaluating work processes, identifying time-consuming activities, and optimizing productivity through methodical analysis.

Educational Value

Students develop critical skills in analyzing and optimizing work processes. They gain expertise in evaluating workflows, implementing improvements, and enhancing productivity. The lab emphasizes data-driven approaches and systematic evaluation, preparing students for industrial management roles where efficiency and resource optimization are paramount. By engaging in these activities, students learn to tackle real-world challenges and develop innovative solutions to improve industrial operations.

DEPARTMENT COMPUTER LABORATORY

Industrial Engineering Computer Lab

Overview

The Department Computer Laboratory serves as a hub for educational activities, providing essential computational resources for data analysis, simulation, and design projects. It supports teaching, research, and the practical application of industrial engineering principles, ensuring that students have access to the tools and technologies needed to succeed in their studies and future careers.

Key Features

Workstations: The lab is equipped with desktop computers that support tasks such as simulation, modeling, data analysis, and computer-aided design (CAD/CAM). Each workstation provides access to industry-standard software tools, enabling students to develop technical proficiency and apply their knowledge to practical challenges.

Collaborative Environment: The lab’s design fosters teamwork and problem-solving skills through interactive discussions and group projects. The presence of posters and educational materials reinforces industrial engineering concepts and serves as visual aids to enhance learning and understanding.

Educational Value

Students develop crucial skills in data analysis, process optimization, and design, which are essential for industrial engineering. The lab supports research and project-based learning, encouraging innovation and collaboration. This environment prepares students for diverse roles in the industry, where computational proficiency is a key asset. By engaging in hands-on activities and working collaboratively, students gain the skills needed to analyze complex systems, optimize processes, and develop innovative solutions to real-world problems.

INDUSTRIAL ROBOTICS LABORATORY

Robotics and Automation Laboratory

Overview

The Industrial Robotics Laboratory specializes in robotic systems and automation technologies used in modern manufacturing. It provides hands-on experience with programming, operating, and integrating robotic systems, equipping students with the skills needed for careers in robotics and automation. The lab emphasizes the importance of robotics in enhancing productivity, precision, and efficiency in industrial processes.

Key Features

Robotic Arms: The lab includes various models such as the Yaskawa Motoman GP8 and SCARA robots, which are used for tasks like assembly, sorting, and pick-and-place operations. These setups allow students to explore robot kinematics, dynamics, and control, gaining practical experience in programming and operating robotic systems.

Conveyor Belt System: Integrated into the lab setup, the conveyor belt system simulates real-world industrial scenarios, enabling students to explore material handling and automation processes. This setup helps students understand the integration of robotics with other manufacturing components, enhancing their ability to design and implement automated solutions.

Educational Value

Students learn about robot programming, sensor integration, and system design, developing solutions for industrial applications. The lab emphasizes the development of practical skills and knowledge in robotics, preparing students for careers where automation plays a pivotal role. By bridging the gap between theory and practice, the lab equips students with the skills needed to excel in the rapidly evolving field of robotics and automation. Students gain hands-on experience with state-of-the-art robotic technologies, enhancing their ability to design, program, and manage robotic systems in industrial settings.

INDUSTRIAL AUTOMATION LAB

PLC-Controlled Industrial Automation Training Stations

Overview

The Industrial Automation Lab provides students with practical experience in automation technologies, focusing on the use of PLCs, sensors, and actuators to control industrial processes. This lab is essential for understanding the complexities of automated systems and the principles of industrial control, preparing students for careers in manufacturing, engineering, and technology.

Key Features

PLC-Controlled Systems: The lab teaches students to program and manage automated systems, including conveyor belts and robotic arms. This fosters skills in system integration and control, emphasizing the role of PLCs as the "brains" of automated systems. Students learn to create control algorithms, coordinate system components, and optimize process performance.

Sensors and Actuators: Essential for real-time process control and optimization, these components enable students to apply theoretical knowledge in practical settings. Students learn how to gather and use data to make informed decisions about process management, enhancing their ability to design and implement automated solutions.

Educational Value

Students develop expertise in automation technologies, system integration, and process optimization, which are crucial for modern manufacturing and industrial automation. The lab bridges the gap between academic learning and real-world application, preparing students for technology-driven careers in industrial engineering. By working with state-of-the-art equipment, students gain valuable insights into the automation processes that drive industrial efficiency. The lab equips students with the skills needed to design, program, and manage complex automated systems, ensuring they are well-prepared for the challenges of modern industrial environments.

HUMAN FACTORS ENGINEERING LABORATORY

Vision and Audiology Testing Station

Overview

The Human Factors Engineering Laboratory focuses on ergonomics and human performance, studying how humans interact with their environments to enhance safety, productivity, and comfort. This lab is crucial for developing ergonomic solutions across various work settings, ensuring that human capabilities and limitations are considered in the design of tools, workspaces, and processes.

Key Features

Purdue Pegboard Dexterity Test: This test measures dexterity and coordination, assessing both gross and fine motor skills essential for tasks requiring manual precision. It provides data on human capabilities that can inform ergonomic designs, helping students understand the importance of designing tasks and tools that align with human capabilities.

Anthropometric Tools: The lab includes digital hand dynamometers, goniometers, and pinch gauges to evaluate physical capabilities such as grip strength and joint range of motion. These tools help design workspaces that minimize injury risks and maximize comfort, allowing students to explore how ergonomic principles can be applied to improve workplace safety and efficiency.

Educational Value

Students gain insights into ergonomic design and sensory performance, developing solutions to improve workplace safety and efficiency. The lab emphasizes the importance of accommodating human abilities and limitations, preparing students for roles in human factors engineering and related fields. By understanding human interactions with technology and environments, students can contribute to safer and more efficient workspaces. The lab equips students with the knowledge and skills needed to design ergonomic solutions that enhance human performance and well-being in various work settings.

COMPUTER INTEGRATED MANUFACTURING (CIM) LAB

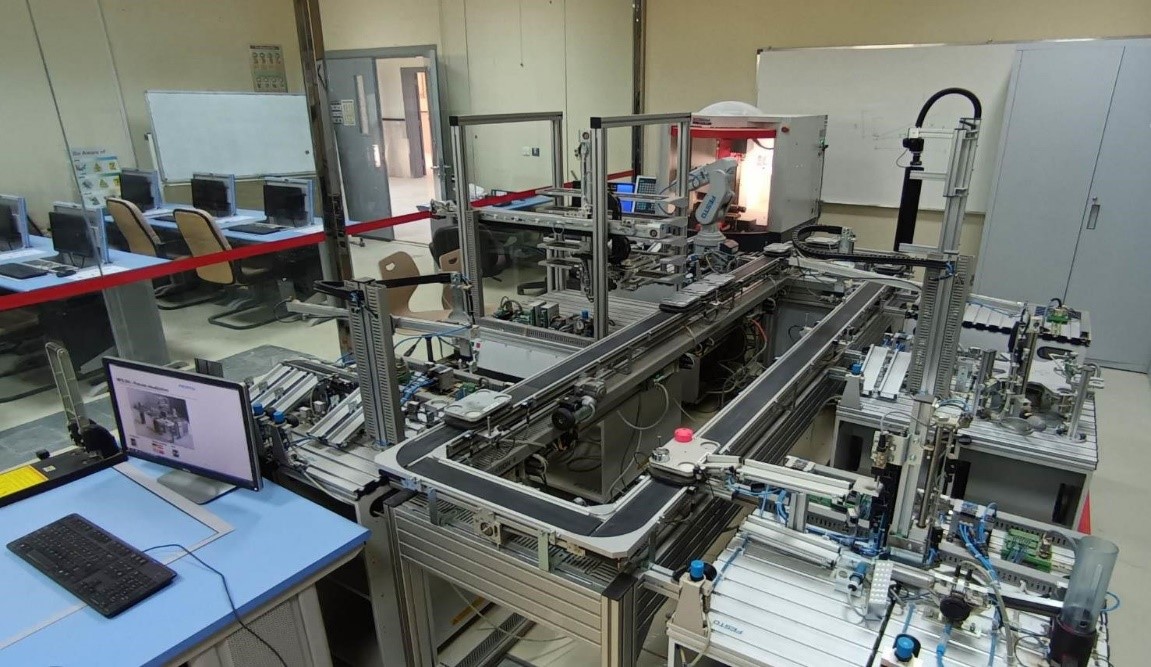

Festo MPS 500 system

Overview

The Computer Integrated Manufacturing (CIM) Lab immerses students in modern manufacturing processes, combining robotics, automation, and computer control to replicate industrial environments. It provides hands-on experience with cutting-edge technologies, allowing students to explore the integration of various manufacturing components and understand the complexities of advanced manufacturing systems.

Key Features

Festo MPS 500 System: Central to the lab, this system includes stations for various manufacturing tasks, such as distribution, processing, handling, storage, sorting, and testing. It illustrates the integration of flexible manufacturing systems, allowing students to explore how different components work together in a cohesive production process.

CNC Machines: These machines enable students to practice machining operations, gaining proficiency in precision manufacturing techniques and learning the fundamentals of computer numerical control (CNC) programming. Students learn to set up workpieces, execute CNC programs, and perform machining operations, providing insights into precision manufacturing.

Educational Value

Students learn about the integration of robotics and automation in manufacturing, preparing them for careers in industrial engineering. The lab supports experiments in flexible manufacturing, robotics programming, and vision system applications, enhancing their technical skills and problem-solving abilities. By experiencing the complete manufacturing cycle, students are better prepared for roles in advanced manufacturing and process optimization. The lab fosters an understanding of how to integrate different manufacturing technologies to create efficient, automated production systems.